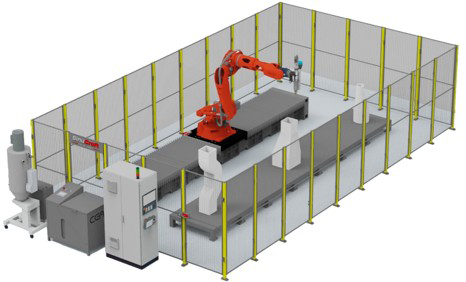

From molds, models, and prototypes to fixtures, architectural sculptures, and design installations. The combination of 3D printing and milling enables fast, accurate, and cost-effective production of even the most complex shapes.

Our hybrid workstations are used by companies in the aerospace, automotive, shipbuilding and construction industries. They are also appreciated by designers, mold makers and research institutions looking for maximum freedom and speed in prototyping.

Czech integrator, Siemens SINUMERIK ONE control system, fast production preparation, Industry 4.0 readiness, and digital twin. With our system, you will reduce production times by up to 30% and gain a competitive edge.

By clicking on the Send button, you confirm that you have read our terms and conditions for the processing of personal data and grant us your consent to contact you with business offers via the email address or telephone number provided. You can modify or revoke this consent at any time.